Acrylic letters - how to make them look like whole?

The answer to this question is clear and definite – double-sided adhesive sheets with specially developed 3M adhesive – 200MP. 3M 200MP meets the customer’s high demands for long-lasting applications.

Thanks to its special properties, the 200MP guarantees a constant adhesive thickness over the entire area of products with smooth surfaces. Products with this 3M dry adhesive are manufactured in different thicknesses (25 – 250 microns) to suit the needs of each production. These are double-sided adhesive tapes and sheets (spacers), specialized for bonding elements in advertising (channel letters, signs) or electronics (dials, keyboards, electronic panels, and others).

3M 200MP is a global quality standard for all industries where it is necessary to bond products with smooth surfaces such as metal, plexiglass and others.

One of 3M’s unique products is the 7955 MPL double-sided adhesive sheet. It is the only 3M adhesive protected by two siliconized protectors. The strong acrylate adhesive absorbs the expansion of dissimilar materials, such as metal and plastic, and does not allow the strength of the connection to weaken. Even heating the materials is not a problem for the 200MP. It withstands high temperatures up to +204°C and tolerates a large linear load.

How the acrylic channel letters with complex shapes are bonded?

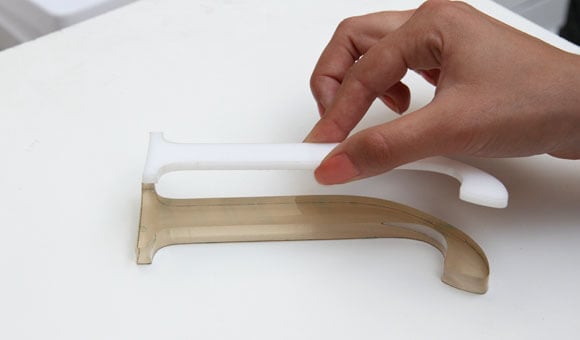

The channel “sandwich” type letters are mostly made of two types plexiglass or stainless steel sheet face and a plexiglass body. The 200MP adhesive in the form of double-sided adhesive sheets 7955MPL is perfect for bonding materials with dissimilar surfaces. Acrylic letters with complex shapes stick perfectly and the connection between the layers of the material is very strong and durable.

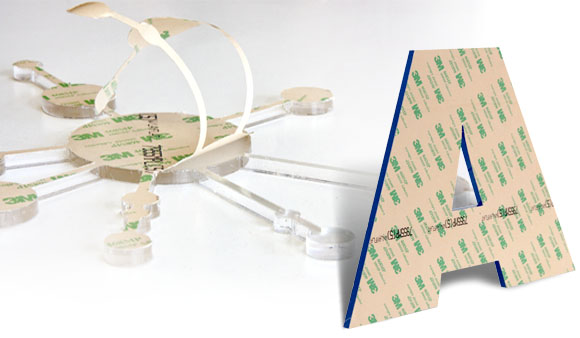

200MP adhesive sheets are easily cut with scissors or a utility knife and can be die-cut and laser-cut. This allows plexiglass letters to be cut along with the 3M adhesive in sheets. The process of making the product is significantly shortened and time is saved. The double-sided tape takes the exact shape of the Plexiglas embossed letters and the finished product has a very good commercial appearance.

Quick and easy manufacturing

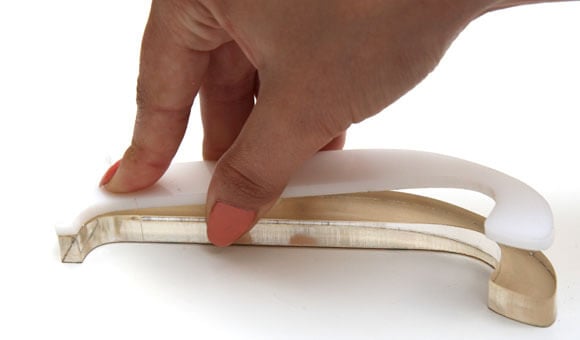

When creating the “sandwich” type of channel letters, there is a possibility that the double-sided tape will be placed askew. This is not a problem. On the contrary, the property of the 200MP adhesive on initial contact provides an opportunity for initial repositioning. In this way, the sheet can be easily adjusted on the Plexiglas surface.

Many advertising signs can be produced self-adhesive, which is a great convenience for customers and advertising installers. 3M 7955 MPL double-sided adhesive sheets mounted on the back of the promotional product can be easily placed on the wall. The strength of the connection is guaranteed for a long time. There is no danger of the 200MP adhesive changing its bond strength when heated or cooled, as the adhesive layer is impurity-free and does not expand or contract.

Assembly stages of embossed acrylic letters:

1. Prepare the two types of plexiglass that should bonded. They are pre-laser cut, along with the adhesive sheet.

2. Peel off the protector of the double-sided adhesive sheet on the top Plexiglas layer.

3. The face of the letter is bonded to the base (in this case with transparent Plexiglas)

4. The two types of plexiglass are lightly pressed

5. The ready self-adhesive product is obtained – a “sandwich” type letter.